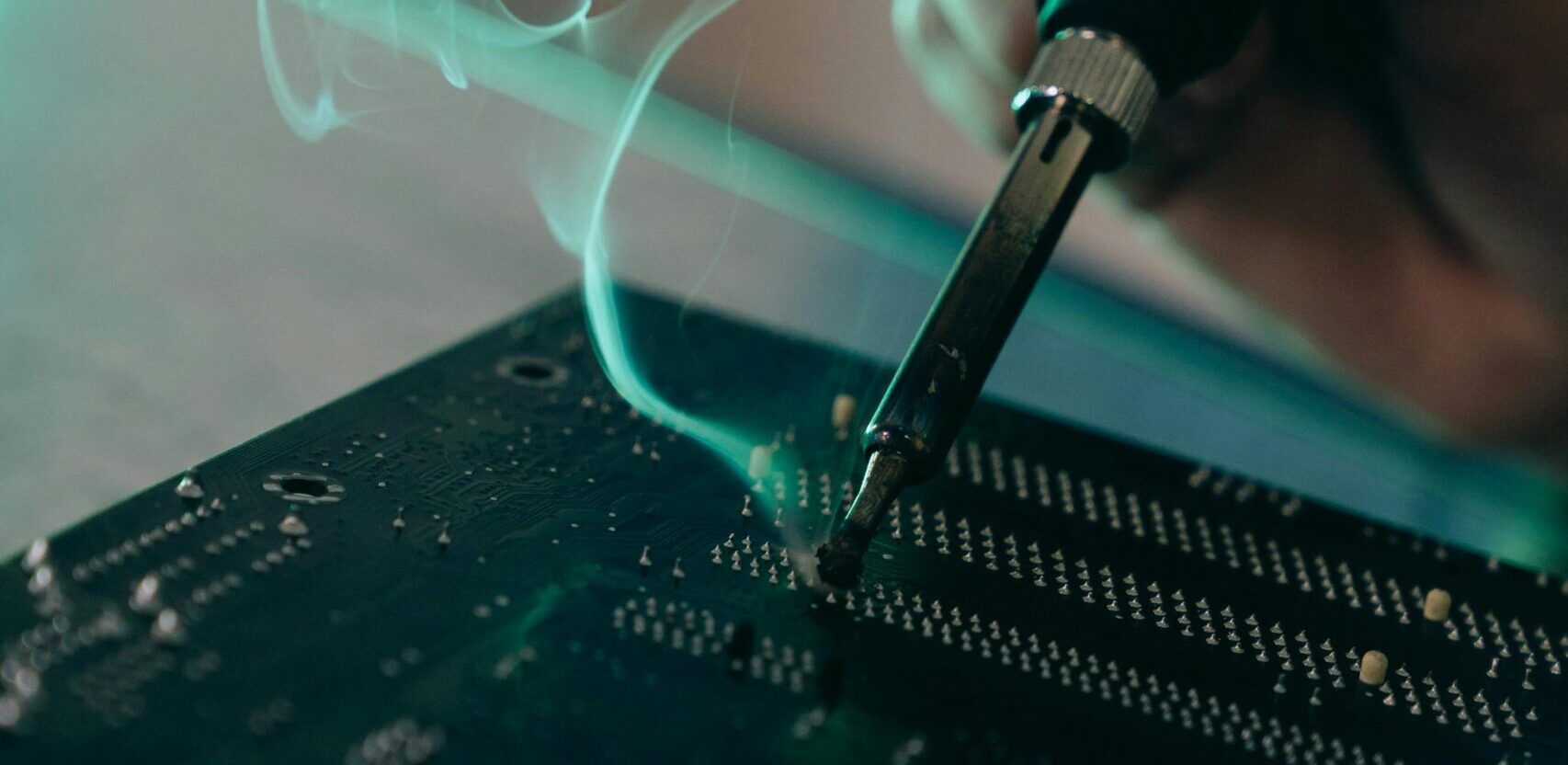

Specialized Services

for Optimal Results

We specialize in a wide array of services, designed to meet the unique needs of each industry we serve. While our expertise extends beyond this list, here are some of the services we excel in:

Manufacturing Engineering

Our experienced manufacturing engineers provide expertise in process optimization, equipment selection, automation, and continuous improvement, enhancing your manufacturing capabilities.

About Us

At Close Consulting, we’re more than just consultants; we’re your strategic partners in optimizing your manufacturing processes. With decades of experience in the industry, our team of manufacturing engineers is dedicated to tackling your most pressing challenges and transforming them into opportunities for growth.

Our Services

- Manufacturing Layout Optimization

Problem: Inefficient manufacturing layouts can lead to wasted time, increased production costs, and reduced overall productivity.

Solution: Our experts will assess your current layout, identify bottlenecks, and design an optimized floor plan that streamlines your production processes.

- Continuous Improvement Strategies

Problem: Stagnation in your manufacturing processes can hinder innovation and cost savings.

Solution: We’ll implement proven continuous improvement methodologies like Lean and Six Sigma to foster a culture of ongoing efficiency enhancements and waste reduction.

- Equipment Selection and Integration

Problem: Choosing the wrong equipment can result in costly mistakes and delays.

Solution: Our team will evaluate your requirements, select the right machinery, and ensure seamless integration into your production line, maximizing ROI.

- Quality Control and Assurance

Problem: Poor quality can tarnish your reputation and lead to customer dissatisfaction.

Solution: We’ll establish robust quality control systems to ensure that your products meet the highest standards, minimizing defects and rework.

- Supply Chain Optimization

Problem: Inefficient supply chains can result in delays and increased costs.

Solution: We’ll help you streamline your supply chain, reduce lead times, and ensure materials are available when needed.

6.Cost Reduction and Profitability Enhancement

Problem: Rising operational costs can eat into your profits.

Solution: Our team will identify cost-saving opportunities, from energy efficiency improvements to labor optimization, to boost your bottom line.

Why Choose Us?

- Expertise: Our team comprises experienced manufacturing engineers with a track record of success.

- Tailored Solutions: We don’t offer one-size-fits-all solutions. Our strategies are customized to your unique needs.

- Results-Driven: We’re committed to delivering measurable improvements in efficiency, quality, and profitability.

- Long-Term Partnership: We’re not just consultants; we’re your partners in long-term success.

Don’t let manufacturing challenges hold you back. Contact Close Consulting today, and let’s work together to take your operations to the next level. Your success is our business!